Recycling

Battery Recycling

Li-Ion Battery Recycling

Lithium-ion batteries have emerged as the powerhouse behind countless devices that shape our lives. From smartphones to electric vehicles (EVs) and renewable energy storage systems, lithium-ion batteries have revolutionized the way we live and consume energy. However, the widespread adoption of these batteries has raised concerns about their environmental impact, particularly in terms of end-of-life disposal and recycling

Evergreen Recyclekaro becomes the first Indian company to achieve over 99% recovery in EV batteries

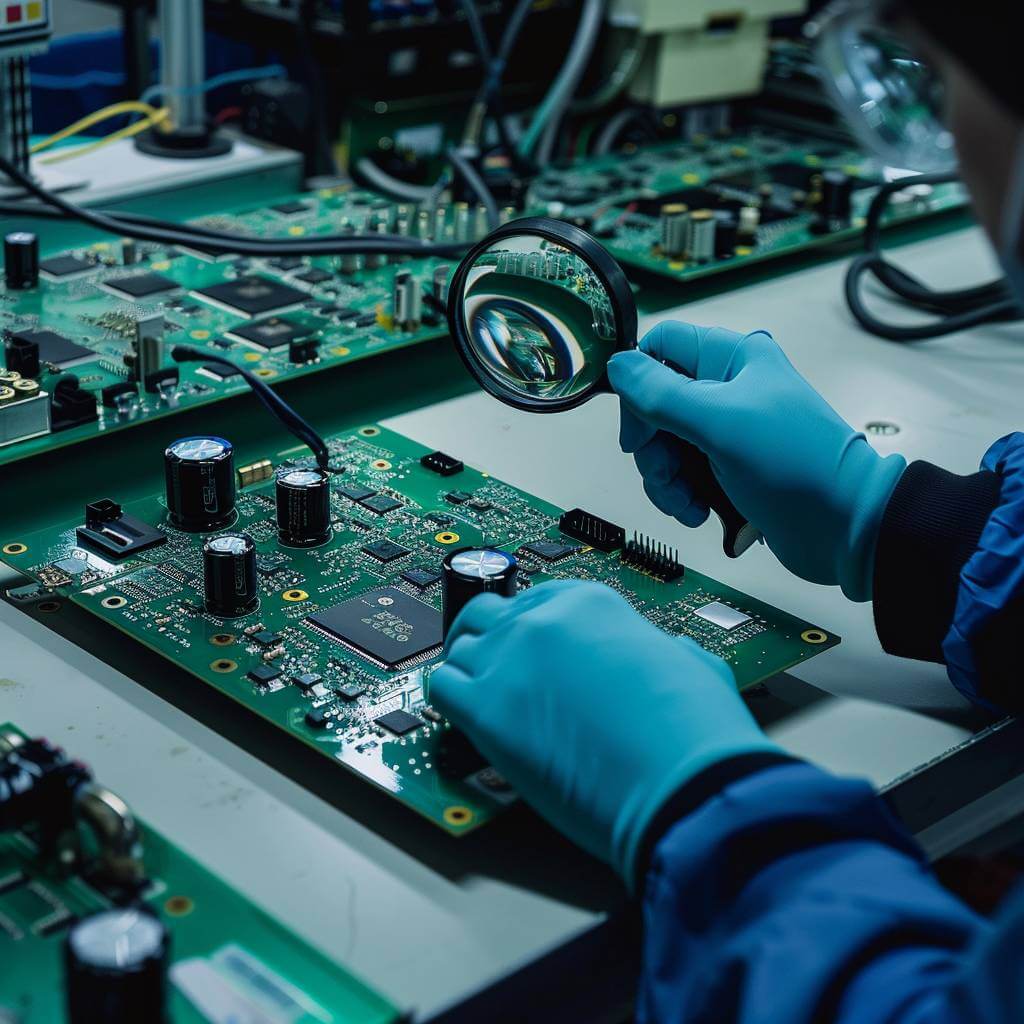

Recycle Karo is at the forefront of driving responsible and sustainable practices within the Li-ion Recycling industry, offering comprehensive solutions that cover the entire spectrum of Li-ion battery recycling processes.

Batteries we Recycle:

Batteries – Lithium-Ion, Nickel Metal Hydride, Nickel Cadmium (rechargeable -NiCad)

Our Commitment

Recycle Karo provides end-to-end solutions encompassing Li-ion battery recycling, ensuring that valuable materials are efficiently and sustainably recovered. Our robust in house R&D systems allow us to adapt operations based on the variability in battery compositions, ensuring efficiency and sustainability throughout the process.

Expertise You Can Trust

With proprietary technology and a wealth of industry knowledge, Recycle Karo is a trusted partner in the Li-ion Recycling sector. We have the capabilities and expertise to deliver sustainable solutions.

Key Drivers for a Sustainable Future

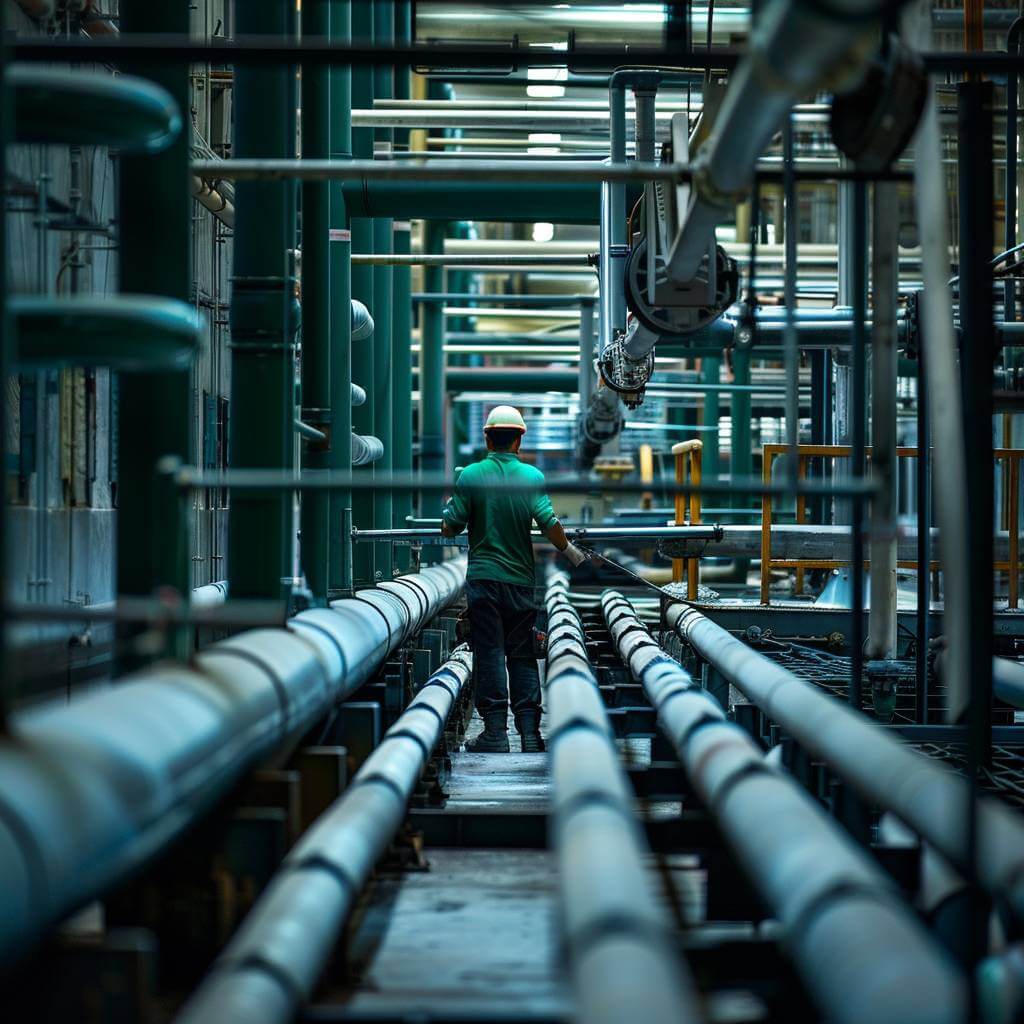

The surging demand for Li-ion batteries, driven by the adoption of electric vehicles, underscores the importance of sustainable practices in the Li-ion Battery Recycling industry. At Recycle Karo, we understand that sustainability must extend beyond individual commodities like lithium, cobalt, nickel, graphite, manganese, copper, and aluminum. We are committed to taking a holistic approach and leading the way toward a more responsible overall business ecosystem.

Recycle Karo in Li-ion Battery Recycling

Recycle Karo's comprehensive technological coverage across the entire Li-ion battery recycling value chain positions us as a leader in driving the transition to sustainable battery-powered alternatives. We offer a unique, responsible value chain that extends from start to finish and beyond, emphasizing sustainability, transparency, safety, and reliability.

- Electric Motor Vehicle/Car

- Laptops/Power tools, mobile phones

- UPS/Backup battery

- Camera Batteries

- Elective Vehicle Batteries

- Car Battery – Lead Acid

- Car Battery – Wet Cell

- Charging Dock Battery

- Portable Power Banks

- Rechargeable batteries

- Battery storage devices

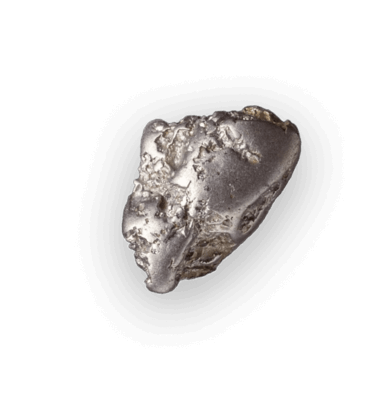

Ni

28

Nickel

58.33

Co

27

Cobalt

58.33

Cu

29

Copper

58.33

Li

3

Lithium

58.33

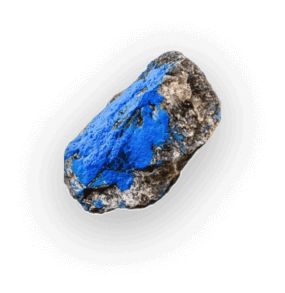

Ni

28

Nickel

58.33

Exploring the Endless Potential of Nickel with Recycle Karo

Nickel: A Sustainable Force

Nickel's outstanding qualities fuel Recycle Karo's sustainability mission. Unlike most elements, nickel can't be created or destroyed, aligning seamlessly with our closed-loop and circular economy principles.

At Recycle Karo, we harness nickel's potential primarily in Li-ion rechargeable batteries, driving innovations in tech and transportation. Our recycling commitment gives old battery nickel a second life.

Today, nickel's main role is in stainless steel, essential in construction and household items. It also adds elegance as a decorative finish.

Recycling

Nickel is fully recyclable, embodying the Circular Economy's spirit by enabling endless repurposing without loss of quality. We lead in recycling nickel from used batteries, reducing waste and enhancing sustainability.

Properties

Nickel, the fifth most common element, shines with qualities like hardness and magnetism. Its role in superalloys for high-stress applications, like jet engines, underscores its versatility.

Join us at Recycle Karo as we harness nickel's boundless potential for a sustainable future.

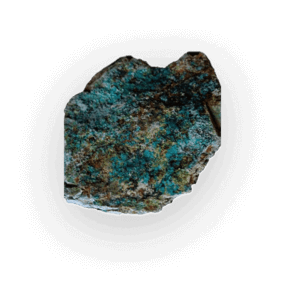

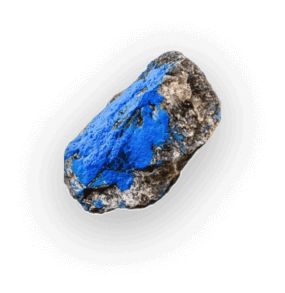

Co

27

Cobalt

58.33

Exploring the Endless Potential of Cobalt with Recycle Karo

Cobalt in Rechargeable Batteries

Cobalt also has a very broad application in rechargeable batteries, mainly of Li-ion type. The incorporation of cobalt in the form of powder improves the electrochemical characteristics of these batteries. Cobalt along with lithium, nickel, and manganese are the critical components in the cathode active material helping to determine how long you can talk on the phone, how far you can drive an electric car, how fast a battery recharges, and how much energy you can store from your solar panels. Recyclekaro is dedicated to promoting the use of cobalt in sustainable energy solutions.

Recycling Cobalt with Recyclekaro

Much of the cobalt is recovered from the production processes of manufacturers of applications like hard metal and cemented carbide tools or Li-ion rechargeable batteries. Cobalt can also be recovered from end-of-life products, such as spent rechargeable batteries, petrochemical catalysts, and alloys used in aerospace applications. Recyclekaro is committed to maximising the recovery of cobalt through efficient recycling processes.

Properties of Cobalt

Cobalt is ferromagnetic, which means it can become magnetised when exposed to an external magnetic field. This is especially useful when mixed with the right metals because it creates superalloys, materials that keep their strength during high stress and high temperatures, making them suitable for applications like jet engines. It crystallises at room temperature in the close-packed hexagonal system (α–Co) and converts to the face-centered cubic form (β–Co) at417°C. It is also a bluish-grey metal, similar to iron and nickel, which is why so many ancient civilisations used it as pigment.

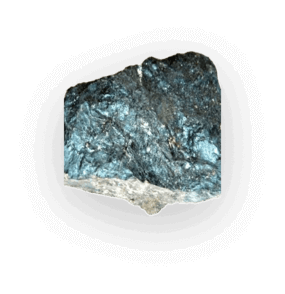

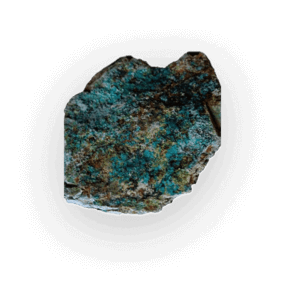

Cu

29

Copper

58.33

Exploring the Endless Potential of Copper with Recycle Karo

Recycling Copper with Recyclekaro

Did you know most copper ore that is mined only contains about 1% of the metal?More than 99% of the copper produced is used in its metallic form, i.e. as copper metal and copper alloys. Recycling rates for copper vary quite considerably by region. Scrap from the forming or shaping of copper and its alloys is generally reprocessed on the spot, either by remelting and adjusting to grade, or by using it as a starting material for less demanding applications. Scrap is also recovered from a range of obsolete goods and appliances — wire, cables, equipment, electronic scrap, motors, fractions from shredding end-of-life cars and household appliances, etc. Recyclekaro is committed to increasing the recycling rates for copper by efficiently processing scrap from various sources.

Historical Significance of Copper

It is not exactly known where and when copper started to be produced from oxidizedores, but the process seems to have been well established around 5500 BC in theNile Valley. Which is why the years after 5000 BC get the name “the CopperAge”. These civilizations later moved to more complex copper alloys and thusintroduced the Bronze Age.

The name ‘copper' is actually derived from the Romans and their mining in Cyprus, where the metal was called cyprium, which was later converted to cuprum. From the 13th to 15th centuries a prosperous copper and brass industry developed inBelgium, especially in the Meuse Valley. Recyclekaro recognizes the historical significance of copper and is committed to preserving its value through efficient recycling practices.

Properties of Copper

Copper is best known for its extremely good conductivity for electricity. It is the only metal to have a clear and specific color, making it one of the only metals which is not silver. Its natural color is salmon pink, but it often appears to be red owing to superficial oxidation.

Au

79

Gold

58.33

Exploring the Endless Potential of Gold with Recyclekaro

Applications of Gold

Now you may not be thinking of investing in eucalyptus trees, but gold is commonly used as an alternative investment in the form of ingots and bars. The main popular image of gold is as a safe haven for investment. Gold's intrinsic valuein the eyes of society has ensured its value throughout history. This value is so great that over 90% of the gold mined in history is still in use, meaningthat we can assume that gold from ancient Egyptian times is still in our economy.

By far the most important use is in jewelry. Being a soft metal, gold is generallyused as an alloy. The grade is expressed in thousandths and in carats, and this is also how its value is measured. Pure gold is equivalent to 24 carats. A22-carat alloy is made up of 92% gold, 5% silver and 3% copper.

The Incas called it 'tears of the sun' because of its brightness and shine, but gold is now used in more than jewelry. Due to its excellent technical properties, a few milligrams of gold can be found in most of our day-to-dayportable devices: it is inside our phones, our laptops and even really old PCs.Gold-palladium alloys offer a wide range of resistivities and are used inresistors and potentiometers too. At Umicore we use electroplating processes tocoat connectors, printed circuit boards or electronic components with thin gold layers. We also use gold or gold alloy for sputtering targets. The gold in suchapplications can be recovered through recycling at the end of their life, we call this urban mining.

Recycling Gold with Recyclekaro

Since gold extraction and mining began, thousands of years ago, less than 200,000 tonnes of gold have been produced, the vast majority of which is still available in above-ground stocks. Recyclekaro differentiates between two types of gold recycling activity.

In short-loop recycling, Recyclekaro recycles customers' residues and production scrap to help them maximize efficiency by transforming the recovered materials into new products. Recyclekaro also receives gold as a secondary material from old jewelry and industrial scrap, and production scrap such as “sweeps”, gold that has been deliberately swept from jewelers' shop floors. These scraps are transformed into new semi-products such as coin blanks, rings, sheets, and tubes used by customers for the same applications and markets.

Long-loop recycling addresses more complex waste streams such as mobile phones and printed circuit boards, and the process to recover valuable materials including gold requires a different and more specialized metallurgical process. While Recyclekaro is a leader in both areas, over 90% of gold recycling of residues, production scrap and old jewelry follows the short loop due to its main high-grade applications. The market is very competitive, and what distinguishes Recyclekaro from other companies is its ability to combine the perfect closed loop with its recycling capabilities and capacities and a complete product portfolio, perfectly matching the demand for recycling to the supply of new qualified products.

Recyclekaro's sustainability approach in the value chain has established its gold production and products as conflict-free. Recyclekaro's CoC gold products are certified by the Responsible Jewelry Council's Chain of Custody program, guaranteeing the integrity of its operations.

Properties of Gold

Gold is a bright yellow metal with a very high density. Along with copper and silver it is one of the best conductors of heat and electricity. It is considered to be the most malleable and ductile of all metals: it can be beaten into semi-transparent foil to a thickness of 0.01 mm, and drawn into thread weighing less than 0.5 g per kilometer.

Ag

47

Silver

58.33

Exploring the Endless Potential of Silver with Recycle Karo

Recycling Silver with Recyclekaro

Silver is recovered from the residues of copper, nickel and lead refining processes, as it is mainly found in ore bodies together with these metals. Silver is also recovered from jewelry, industrial scrap and end-of-life applications such as electronic and electrical scrap.

Not only does this benefit the recovery of silver itself, but silver also helps to recover other (precious) metals, as it is often a collector metal (or “carrier” for other precious metals) in the refining process itself.

Within Recyclekaro's closed loop business model, silver - in combination with gold - has been the focus of customers' expectations right from the start, followed by PGM recycling. In addition, recycled silver not only supports the customer's resource efficiency but also helps to maintain Recyclekaro's influx of raw materials for its semi-finished products that are based on silver or silver alloys.

So silver is a key element for recycling. Several Recyclekaro business sites have therefore established increased electro-chemical refining capacities for silver.

Historical Significance of Silver

Did you know that in the Middle Ages, when people talked about silver, they actually meant money? It was during this period that silver mines began to be exploited throughout Europe. The discovery of silver deposits in the ‘New World’ after 1492 had a huge impact on the role of silver throughout the world and mining of silver thereafter dramatically eclipsed anything that had come before.

Between 1500 and 1800, Bolivia, Peru and Mexico accounted for over 85 percent of world production and trade. The term silver continued to be used in the sense of money in several countries, even becoming the name of theUK’s currency. Pound sterling referred to the weight of the coin of silver in pounds!

Properties of Silver

Did you know that silver means shiny in Latin? The chemical symbol of silver (Ag) derives from the word argentum which means white or shining. This suits silver perfectly as it is a shiny white metal, more ductile and malleable than copper, but slightly less so than gold. Its electrical and thermal conductivities are higher than those of any other metal; its electrical conductivity is 8% higher than that of copper.

When solidified in air, the metal presents a blistered surface because of the release of dissolved oxygen.

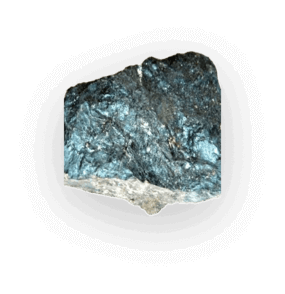

Li

3

Lithium

58.33

Exploring the Endless Potential of Lithium with Recycle Karo

Recycling Lithium with Recyclekaro

Due to the abundance of lithium in nature, recycling of lithium was not a priority for the many players in the lithium-ion battery, glass, or ceramics industries.The recent increase in demand for lithium for electric vehicles has emphasised the importance of recycling, and now both pyrometallurgical and hydrometallurgical flowsheets can recycle lithium from Li-ion battery waste. Recyclekaro is closing the loop for lithium.

Extraction of Lithium

The mining of pegmatitic minerals containing spodumene (LiAl(SiO3)2) is mainly located in Western Australia. After a series of mechanical purification and separation steps, the lithium in the mined minerals can be concentrated. The attained spodumene concentrate can be used directly in industries such as glass manufacturing or can be further refined into a lithium chemical. Lithium owes its name to the Greek word lithos, which means stone, as around half of industrially used lithium is extracted from hard rock deposits. The other source of lithium is from brine-based sources. The majority of these salt solutions are found in the salt flats that cover parts of Chile, Argentina, andBolivia: the so-called lithium triangle. The lithium dissolved in brines is concentrated by solar evaporation, followed by a combination of precipitation and filtration steps to remove residual impurities such as calcium, magnesium, and boron. The purified LiCl solution can then be used to make a variety of lithium chemicals.

Properties of Lithium

Did you know that along with hydrogen and helium, lithium was one of the three elements produced in large quantities by the Big Bang? The main problem with the isolation of lithium in its metallic form is its high reactivity and flammability.Consequently, you won’t find this element as a pure metal in nature but as a compound or in its soluble ionic form. Compared to other alkali metals however, lithium is less reactive due to its small atomic radius (152 pm) and the proximity of its single valence electron to the nucleus, which stabilises the electron. Other properties that make lithium a unique element are its low density (0.534 g/cm3) and its high specific heat capacity (3.58 kJ/(kg K), the highest of all solids. This has led to a variety of industrial applications that use lithium.

Mn

25

Managanese

58.33

Exploring the Endless Potential of Managanese with Recycle Karo

Recycling Manganese with Recyclekaro

Manganese mines can be found all over the world. The highest concentration of reserves and mining activity are located in South Africa. The main market for manganese is in the form of manganese ore, which is shipped to China for further processing into stainless steel and other applications. Other forms of manganese are mainly manganese metal and chemicals. The latter being the market segment in which Umicore sources manganese for its rechargeable battery materials activities.

Properties of Manganese

Manganese is a hard, but very brittle metal with a pink-gray color. When pure, manganese can be very reactive, and as a powder, it can burn in oxygen. It is very easily oxidized and, like iron, it reacts to water and rusts. It is also very hard to melt.

Nd

60

Neodymium

58.33

Exploring the Endless Potential of Neodymium with Recycle Karo

Recycling Neodymium with Recyclekaro

Rare earths like neodymium are very challenging to recycle due partly to their very dispersed use. Recyclekaro is committed to developing innovative recycling technologies and processes to efficiently recover neodymium and other rare earths from end-of-life products and industrial waste streams, contributing toa more sustainable use of these valuable resources..

Properties of Neodymium

Neodymium is a soft, bright, silvery white metal and one of the lanthanide rare earth metals. It forms a flaky oxide coating in air, which, unlike many metal oxide layers, does not protect the metal from further oxidation. Neodymium has two allotropic forms, transforming from hexagonal to body-centered cubic above 800K(527°C), and usually exists as a trivalent ion, Nd3+, in its compounds. Most of its salts are pale purple in color.

Pd

46

Palladium

58.33

Exploring the Endless Potential of Palladium with Recycle Karo

Recycling Palladium with Recyclekaro

Most of the world's palladium is extracted as a byproduct of other metals such as platinum and nickel. However, recycling is providing an increasingly sizable proportion of the overall supply. Palladium can be infinitely recycled without losing its intrinsic characteristics and because of its high value, it is recycled quite readily. Most of the recycled volumes come from spent automotive catalysts as well as old jewelry, with electronics making up the remainder. Recyclekaro is one of the leaders in recycling spent automotive catalysts, contributing to the circular economy by recovering palladium and other precious metals. Nevertheless, following the sharp rise in the consumption of palladium in automotive catalysts over the past few years, the current secondary supply is still much lower than global demand for the metal.

Properties of Palladium

Palladium is a shiny white metal that resembles platinum and has the lowest volumetric mass and the lowest melting point of all the platinum-group metals (PGM).

Palladium is one of the most abundant platinum metals and occurs in the earth's crust in proportions of 0.015 part per million; it is also found alloyed with native platinum.

At room temperature, it is capable of absorbing 600 to 900 times its own volume of hydrogen, depending on its physical state. This capacity is probably due to the formation of a solid solution between the metal and its own hydride, Pd2H. Ashydrogen is absorbed, the metal expands. Under slight pressure, hydrogen diffuses into the palladium and is thereby purified of any accompanying gases.

Historical Significance of Palladium

Palladium was identified in 1803 by the chemist and physicist William Hyde Wollaston in the residue after attacking impure platinum with aqua regia. He named the element after the newly discovered asteroid Pallas.

Rh

45

Rhodium

58.33

Exploring the Endless Potential of Rhodium with Recycle Karo

Properties of Rhodium

Rhodium is a very hard metal and one of the strongest mechanically. It belongs to the platinum group metals, which also include platinum, palladium, osmium, iridium, and ruthenium. Rhodium has a lower density and a higher melting point than platinum. It is classified as a noble metal, meaning that it does not easily react to oxygen, acts as a fantastic catalyst, and is resistant to corrosion and oxidation.

Recycling Rhodium with Recyclekaro

Rhodium is mainly recycled from spent automotive catalysts, with a small portion coming from closed-loop recycling in the glass industry. Due to its special properties and limited use in various applications, recycling rhodium is technically and economically challenging. However, about one-third of the global rhodium supply comes from recycling, highlighting its significant role in the market. Recyclekaro is one of the few companies worldwide with the expertise to recycle rhodium, contributing to sustainable metal management practices.

History of Rhodium

Rhodium was identified in 1804 by English chemist William Hyde Wollaston, who also discovered palladium. He extracted rhodium from a piece of platinum ore obtained from South America. The name "rhodium" is derived from the Greek word "ροδον" (pink) due to the pinkish-red color of rhodium salts.

Ru

44

Ruthenium

58.33

Exploring the Endless Potential of Ruthenium with Recycle Karo

Use

- Ruthenium is highly valued for its versatility in various industrial applications, including electronics, catalysis, and jewelry.

- It is used as a catalyst in the production of chemicals like ammonia and as a hardening agent in platinum and palladium alloys for jewelry.

- Ruthenium-based compounds are also utilized in electronics for memory devices and as a coating material for electrical contacts.

Properties of Ruthenium

- Ruthenium is a dense, corrosion-resistant metal with a silvery-white appearance.

- It has a high melting point of 2,334°C and exhibits good electrical conductivity.

- Ruthenium is chemically stable and resistant to acids and oxidation.

Recycling Ruthenium with RecycleKaro:

- Ruthenium can be recycled from various industrial processes, including the production of platinum group metals and electronic waste.

- Recycling ruthenium helps conserve resources and reduce environmental impact, though it requires specialized techniques due to its low abundance and dispersed use.

Ir

77

Iridium

58.33

Exploring the Endless Potential of Iridium with Recycle Karo

Applications of Iridium

Iridium is prized for its durability and resistance to corrosion, finding applications in spark plugs, electrical contacts, high-temperature crucibles, jewelry alloys, and specialized devices.

Properties of Iridium

Iridium is exceptionally dense, corrosion-resistant, and has a high melting point of 2,447°C. It is one of the least reactive metals even at high temperatures and in corrosive environments. Iridium is extremely hard and brittle.

Recycling Iridium with RecycleKaro

Iridium is recycled from various sources like spent catalysts, old spark plugs, and electronic components. Recycling conserves resources, reduces environmental impact, and meets industry demand. However, recycling iridium is challenging due to its chemical properties, requiring specialized techniques for extraction and purification.

In

49

Indium

58.33

Exploring the Endless Potential of Indium with Recycle Karo

Applications of indium

- Indium is valued for its unique properties in various applications such as in the production of touchscreens, liquid crystal displays (LCDs), solar panels, and semiconductors.

- It is also used as a coating material for bearings and in certain types of solder.

Properties of Indium

- Indium is a soft, malleable, and ductile metal with a low melting point, making it ideal for applications where it needs to form a bond at relatively low temperatures

- It has good electrical conductivity and is highly resistant to corrosion

Recycling Indium with RecycleKaro

Indium can be recycled from end-of-life electronic devices like LCD screens, semiconductors, and solder. Recycling indium helps conserve resources, reduce waste, and meet the demand for this valuable material in various industries. However, the process requires specialized techniques for efficient extraction and purification

Ta

73

Tantallum

58.33

Exploring the Endless Potential of Tantallum with Recycle Karo

Applications of Tantalum

- Highly valued for corrosion resistance and high electrical charge retention, crucial in electronics manufacturing

- Primarily used in capacitors for smartphones, laptops, and medical implants, and in aerospace and chemical processing for heat and corrosion resistance.

Properties of Tantallum

- Dense, ductile metal with outstanding corrosion resistance, especially to acids

- High melting point of 3,020°C, suitable for high-temperature applications

- Exhibits good heat and electrical conductivity

Recycling Tantalum with RecycleKaro

- Tantalum is recycled from electronic devices and industrial waste, reducing environmental impact and conserving resources

- Requires specialized techniques for efficient separation from other materials

Boosting Circular Economy

Evergreen Recyclekaro becomes the first Indian company to achieve over 99% recovery in EV batteries

These five key metals constitute 50-60% of the cost of lithium-ion batteries. Recycling and re-using these key metals will have a direct impact on the volume of import and overall cost of batteries and will also improve the national stock levels of these metals.

Cobalt

Used in cathode for all type of lithium-ion batteries except lithium iron phosphate battery

Nickel

Used in cathode for Lithium Nickel Cobalt Aluminium Oxide (batteries)

Australia has the largest reserves (24%), followed by Brazil and Russia

Avg Price(2023) : 29,427 USD/ tonne

Lithium

Used in the cathode of all kind of lithium-ion batteries

75% of the world reserves exist in Argentina, Chile, and Bolivia

Avg Price(2023) : 79,300 USD/ tonne

Copper

Used in collector foil, electrical tabs, connections and functional items at cell and pack level

Chile (20.5%) has the largest reserves, followed by Australia and Peru

Avg Price(2023) : 9,329 USD/ tonne

Graphite

All lithium-ion batteries use graphite as anode

China accounts for almost 60% of the graphite reserves

Avg Price(2023) : 2,116 USD/ tonne

Impact

80000 T

Valuable materials recovered

80%

e-waste recycle back into new products

3400 T

Battery waste diverted from landfill

3400

4th impact to be added here in this section

6000

5th impact to be added here in this section

500000

6th impact to be added here in this section

Ni

28

Nickel

58.33

Exploring the Endless Potential of Nickel with Recycle Karo

Nickel: A Sustainable Force

Nickel's outstanding qualities fuel Recycle Karo's sustainability mission. Unlike most elements, nickel can't be created or destroyed, aligning seamlessly with our closed-loop and circular economy principles.

At Recycle Karo, we harness nickel's potential primarily in Li-ion rechargeable batteries, driving innovations in tech and transportation. Our recycling commitment gives old battery nickel a second life.

Today, nickel's main role is in stainless steel, essential in construction and household items. It also adds elegance as a decorative finish.

Recycling

Nickel is fully recyclable, embodying the Circular Economy's spirit by enabling endless repurposing without loss of quality. We lead in recycling nickel from used batteries, reducing waste and enhancing sustainability.

Properties

Nickel, the fifth most common element, shines with qualities like hardness and magnetism. Its role in superalloys for high-stress applications, like jet engines, underscores its versatility.

Join us at Recycle Karo as we harness nickel's boundless potential for a sustainable future.

Co

27

Cobalt

58.33

Exploring the Endless Potential of Cobalt with Recycle Karo

Cobalt in Rechargeable Batteries

Cobalt also has a very broad application in rechargeable batteries, mainly of Li-ion type. The incorporation of cobalt in the form of powder improves the electrochemical characteristics of these batteries. Cobalt along with lithium, nickel, and manganese are the critical components in the cathode active material helping to determine how long you can talk on the phone, how far you can drive an electric car, how fast a battery recharges, and how much energy you can store from your solar panels. Recyclekaro is dedicated to promoting the use of cobalt in sustainable energy solutions.

Recycling Cobalt with Recyclekaro

Much of the cobalt is recovered from the production processes of manufacturers of applications like hard metal and cemented carbide tools or Li-ion rechargeable batteries. Cobalt can also be recovered from end-of-life products, such as spent rechargeable batteries, petrochemical catalysts, and alloys used in aerospace applications. Recyclekaro is committed to maximising the recovery of cobalt through efficient recycling processes.

Properties of Cobalt

Cobalt is ferromagnetic, which means it can become magnetised when exposed to an external magnetic field. This is especially useful when mixed with the right metals because it creates superalloys, materials that keep their strength during high stress and high temperatures, making them suitable for applications like jet engines. It crystallises at room temperature in the close-packed hexagonal system (α–Co) and converts to the face-centered cubic form (β–Co) at417°C. It is also a bluish-grey metal, similar to iron and nickel, which is why so many ancient civilisations used it as pigment.

Cu

29

Copper

58.33

Exploring the Endless Potential of Copper with Recycle Karo

Recycling Copper with Recyclekaro

Did you know most copper ore that is mined only contains about 1% of the metal?More than 99% of the copper produced is used in its metallic form, i.e. as copper metal and copper alloys. Recycling rates for copper vary quite considerably by region. Scrap from the forming or shaping of copper and its alloys is generally reprocessed on the spot, either by remelting and adjusting to grade, or by using it as a starting material for less demanding applications. Scrap is also recovered from a range of obsolete goods and appliances — wire, cables, equipment, electronic scrap, motors, fractions from shredding end-of-life cars and household appliances, etc. Recyclekaro is committed to increasing the recycling rates for copper by efficiently processing scrap from various sources.

Historical Significance of Copper

It is not exactly known where and when copper started to be produced from oxidizedores, but the process seems to have been well established around 5500 BC in theNile Valley. Which is why the years after 5000 BC get the name “the CopperAge”. These civilizations later moved to more complex copper alloys and thusintroduced the Bronze Age.

The name ‘copper' is actually derived from the Romans and their mining in Cyprus, where the metal was called cyprium, which was later converted to cuprum. From the 13th to 15th centuries a prosperous copper and brass industry developed inBelgium, especially in the Meuse Valley. Recyclekaro recognizes the historical significance of copper and is committed to preserving its value through efficient recycling practices.

Properties of Copper

Copper is best known for its extremely good conductivity for electricity. It is the only metal to have a clear and specific color, making it one of the only metals which is not silver. Its natural color is salmon pink, but it often appears to be red owing to superficial oxidation.

Au

79

Gold

58.33

Exploring the Endless Potential of Gold with Recyclekaro

Applications of Gold

Now you may not be thinking of investing in eucalyptus trees, but gold is commonly used as an alternative investment in the form of ingots and bars. The main popular image of gold is as a safe haven for investment. Gold's intrinsic valuein the eyes of society has ensured its value throughout history. This value is so great that over 90% of the gold mined in history is still in use, meaningthat we can assume that gold from ancient Egyptian times is still in our economy.

By far the most important use is in jewelry. Being a soft metal, gold is generallyused as an alloy. The grade is expressed in thousandths and in carats, and this is also how its value is measured. Pure gold is equivalent to 24 carats. A22-carat alloy is made up of 92% gold, 5% silver and 3% copper.

The Incas called it 'tears of the sun' because of its brightness and shine, but gold is now used in more than jewelry. Due to its excellent technical properties, a few milligrams of gold can be found in most of our day-to-dayportable devices: it is inside our phones, our laptops and even really old PCs.Gold-palladium alloys offer a wide range of resistivities and are used inresistors and potentiometers too. At Umicore we use electroplating processes tocoat connectors, printed circuit boards or electronic components with thin gold layers. We also use gold or gold alloy for sputtering targets. The gold in suchapplications can be recovered through recycling at the end of their life, we call this urban mining.

Recycling Gold with Recyclekaro

Since gold extraction and mining began, thousands of years ago, less than 200,000 tonnes of gold have been produced, the vast majority of which is still available in above-ground stocks. Recyclekaro differentiates between two types of gold recycling activity.

In short-loop recycling, Recyclekaro recycles customers' residues and production scrap to help them maximize efficiency by transforming the recovered materials into new products. Recyclekaro also receives gold as a secondary material from old jewelry and industrial scrap, and production scrap such as “sweeps”, gold that has been deliberately swept from jewelers' shop floors. These scraps are transformed into new semi-products such as coin blanks, rings, sheets, and tubes used by customers for the same applications and markets.

Long-loop recycling addresses more complex waste streams such as mobile phones and printed circuit boards, and the process to recover valuable materials including gold requires a different and more specialized metallurgical process. While Recyclekaro is a leader in both areas, over 90% of gold recycling of residues, production scrap and old jewelry follows the short loop due to its main high-grade applications. The market is very competitive, and what distinguishes Recyclekaro from other companies is its ability to combine the perfect closed loop with its recycling capabilities and capacities and a complete product portfolio, perfectly matching the demand for recycling to the supply of new qualified products.

Recyclekaro's sustainability approach in the value chain has established its gold production and products as conflict-free. Recyclekaro's CoC gold products are certified by the Responsible Jewelry Council's Chain of Custody program, guaranteeing the integrity of its operations.

Properties of Gold

Gold is a bright yellow metal with a very high density. Along with copper and silver it is one of the best conductors of heat and electricity. It is considered to be the most malleable and ductile of all metals: it can be beaten into semi-transparent foil to a thickness of 0.01 mm, and drawn into thread weighing less than 0.5 g per kilometer.

Ag

47

Silver

58.33

Exploring the Endless Potential of Silver with Recycle Karo

Recycling Silver with Recyclekaro

Silver is recovered from the residues of copper, nickel and lead refining processes, as it is mainly found in ore bodies together with these metals. Silver is also recovered from jewelry, industrial scrap and end-of-life applications such as electronic and electrical scrap.

Not only does this benefit the recovery of silver itself, but silver also helps to recover other (precious) metals, as it is often a collector metal (or “carrier” for other precious metals) in the refining process itself.

Within Recyclekaro's closed loop business model, silver - in combination with gold - has been the focus of customers' expectations right from the start, followed by PGM recycling. In addition, recycled silver not only supports the customer's resource efficiency but also helps to maintain Recyclekaro's influx of raw materials for its semi-finished products that are based on silver or silver alloys.

So silver is a key element for recycling. Several Recyclekaro business sites have therefore established increased electro-chemical refining capacities for silver.

Historical Significance of Silver

Did you know that in the Middle Ages, when people talked about silver, they actually meant money? It was during this period that silver mines began to be exploited throughout Europe. The discovery of silver deposits in the ‘New World’ after 1492 had a huge impact on the role of silver throughout the world and mining of silver thereafter dramatically eclipsed anything that had come before.

Between 1500 and 1800, Bolivia, Peru and Mexico accounted for over 85 percent of world production and trade. The term silver continued to be used in the sense of money in several countries, even becoming the name of theUK’s currency. Pound sterling referred to the weight of the coin of silver in pounds!

Properties of Silver

Did you know that silver means shiny in Latin? The chemical symbol of silver (Ag) derives from the word argentum which means white or shining. This suits silver perfectly as it is a shiny white metal, more ductile and malleable than copper, but slightly less so than gold. Its electrical and thermal conductivities are higher than those of any other metal; its electrical conductivity is 8% higher than that of copper.

When solidified in air, the metal presents a blistered surface because of the release of dissolved oxygen.

Li

3

Lithium

58.33

Exploring the Endless Potential of Lithium with Recycle Karo

Recycling Lithium with Recyclekaro

Due to the abundance of lithium in nature, recycling of lithium was not a priority for the many players in the lithium-ion battery, glass, or ceramics industries.The recent increase in demand for lithium for electric vehicles has emphasised the importance of recycling, and now both pyrometallurgical and hydrometallurgical flowsheets can recycle lithium from Li-ion battery waste. Recyclekaro is closing the loop for lithium.

Extraction of Lithium

The mining of pegmatitic minerals containing spodumene (LiAl(SiO3)2) is mainly located in Western Australia. After a series of mechanical purification and separation steps, the lithium in the mined minerals can be concentrated. The attained spodumene concentrate can be used directly in industries such as glass manufacturing or can be further refined into a lithium chemical. Lithium owes its name to the Greek word lithos, which means stone, as around half of industrially used lithium is extracted from hard rock deposits. The other source of lithium is from brine-based sources. The majority of these salt solutions are found in the salt flats that cover parts of Chile, Argentina, andBolivia: the so-called lithium triangle. The lithium dissolved in brines is concentrated by solar evaporation, followed by a combination of precipitation and filtration steps to remove residual impurities such as calcium, magnesium, and boron. The purified LiCl solution can then be used to make a variety of lithium chemicals.

Properties of Lithium

Did you know that along with hydrogen and helium, lithium was one of the three elements produced in large quantities by the Big Bang? The main problem with the isolation of lithium in its metallic form is its high reactivity and flammability.Consequently, you won’t find this element as a pure metal in nature but as a compound or in its soluble ionic form. Compared to other alkali metals however, lithium is less reactive due to its small atomic radius (152 pm) and the proximity of its single valence electron to the nucleus, which stabilises the electron. Other properties that make lithium a unique element are its low density (0.534 g/cm3) and its high specific heat capacity (3.58 kJ/(kg K), the highest of all solids. This has led to a variety of industrial applications that use lithium.

Mn

25

Managanese

58.33

Exploring the Endless Potential of Managanese with Recycle Karo

Recycling Manganese with Recyclekaro

Manganese mines can be found all over the world. The highest concentration of reserves and mining activity are located in South Africa. The main market for manganese is in the form of manganese ore, which is shipped to China for further processing into stainless steel and other applications. Other forms of manganese are mainly manganese metal and chemicals. The latter being the market segment in which Umicore sources manganese for its rechargeable battery materials activities.

Properties of Manganese

Manganese is a hard, but very brittle metal with a pink-gray color. When pure, manganese can be very reactive, and as a powder, it can burn in oxygen. It is very easily oxidized and, like iron, it reacts to water and rusts. It is also very hard to melt.

Nd

60

Neodymium

58.33

Exploring the Endless Potential of Neodymium with Recycle Karo

Recycling Neodymium with Recyclekaro

Rare earths like neodymium are very challenging to recycle due partly to their very dispersed use. Recyclekaro is committed to developing innovative recycling technologies and processes to efficiently recover neodymium and other rare earths from end-of-life products and industrial waste streams, contributing toa more sustainable use of these valuable resources..

Properties of Neodymium

Neodymium is a soft, bright, silvery white metal and one of the lanthanide rare earth metals. It forms a flaky oxide coating in air, which, unlike many metal oxide layers, does not protect the metal from further oxidation. Neodymium has two allotropic forms, transforming from hexagonal to body-centered cubic above 800K(527°C), and usually exists as a trivalent ion, Nd3+, in its compounds. Most of its salts are pale purple in color.

Pd

46

Palladium

58.33

Exploring the Endless Potential of Palladium with Recycle Karo

Recycling Palladium with Recyclekaro

Most of the world's palladium is extracted as a byproduct of other metals such as platinum and nickel. However, recycling is providing an increasingly sizable proportion of the overall supply. Palladium can be infinitely recycled without losing its intrinsic characteristics and because of its high value, it is recycled quite readily. Most of the recycled volumes come from spent automotive catalysts as well as old jewelry, with electronics making up the remainder. Recyclekaro is one of the leaders in recycling spent automotive catalysts, contributing to the circular economy by recovering palladium and other precious metals. Nevertheless, following the sharp rise in the consumption of palladium in automotive catalysts over the past few years, the current secondary supply is still much lower than global demand for the metal.

Properties of Palladium

Palladium is a shiny white metal that resembles platinum and has the lowest volumetric mass and the lowest melting point of all the platinum-group metals (PGM).

Palladium is one of the most abundant platinum metals and occurs in the earth's crust in proportions of 0.015 part per million; it is also found alloyed with native platinum.

At room temperature, it is capable of absorbing 600 to 900 times its own volume of hydrogen, depending on its physical state. This capacity is probably due to the formation of a solid solution between the metal and its own hydride, Pd2H. Ashydrogen is absorbed, the metal expands. Under slight pressure, hydrogen diffuses into the palladium and is thereby purified of any accompanying gases.

Historical Significance of Palladium

Palladium was identified in 1803 by the chemist and physicist William Hyde Wollaston in the residue after attacking impure platinum with aqua regia. He named the element after the newly discovered asteroid Pallas.

Rh

45

Rhodium

58.33

Exploring the Endless Potential of Rhodium with Recycle Karo

Properties of Rhodium

Rhodium is a very hard metal and one of the strongest mechanically. It belongs to the platinum group metals, which also include platinum, palladium, osmium, iridium, and ruthenium. Rhodium has a lower density and a higher melting point than platinum. It is classified as a noble metal, meaning that it does not easily react to oxygen, acts as a fantastic catalyst, and is resistant to corrosion and oxidation.

Recycling Rhodium with Recyclekaro

Rhodium is mainly recycled from spent automotive catalysts, with a small portion coming from closed-loop recycling in the glass industry. Due to its special properties and limited use in various applications, recycling rhodium is technically and economically challenging. However, about one-third of the global rhodium supply comes from recycling, highlighting its significant role in the market. Recyclekaro is one of the few companies worldwide with the expertise to recycle rhodium, contributing to sustainable metal management practices.

History of Rhodium

Rhodium was identified in 1804 by English chemist William Hyde Wollaston, who also discovered palladium. He extracted rhodium from a piece of platinum ore obtained from South America. The name "rhodium" is derived from the Greek word "ροδον" (pink) due to the pinkish-red color of rhodium salts.

Ru

44

Ruthenium

58.33

Exploring the Endless Potential of Ruthenium with Recycle Karo

Use

- Ruthenium is highly valued for its versatility in various industrial applications, including electronics, catalysis, and jewelry.

- It is used as a catalyst in the production of chemicals like ammonia and as a hardening agent in platinum and palladium alloys for jewelry.

- Ruthenium-based compounds are also utilized in electronics for memory devices and as a coating material for electrical contacts.

Properties of Ruthenium

- Ruthenium is a dense, corrosion-resistant metal with a silvery-white appearance.

- It has a high melting point of 2,334°C and exhibits good electrical conductivity.

- Ruthenium is chemically stable and resistant to acids and oxidation.

Recycling Ruthenium with RecycleKaro:

- Ruthenium can be recycled from various industrial processes, including the production of platinum group metals and electronic waste.

- Recycling ruthenium helps conserve resources and reduce environmental impact, though it requires specialized techniques due to its low abundance and dispersed use.

Ir

77

Iridium

58.33

Exploring the Endless Potential of Iridium with Recycle Karo

Applications of Iridium

Iridium is prized for its durability and resistance to corrosion, finding applications in spark plugs, electrical contacts, high-temperature crucibles, jewelry alloys, and specialized devices.

Properties of Iridium

Iridium is exceptionally dense, corrosion-resistant, and has a high melting point of 2,447°C. It is one of the least reactive metals even at high temperatures and in corrosive environments. Iridium is extremely hard and brittle.

Recycling Iridium with RecycleKaro

Iridium is recycled from various sources like spent catalysts, old spark plugs, and electronic components. Recycling conserves resources, reduces environmental impact, and meets industry demand. However, recycling iridium is challenging due to its chemical properties, requiring specialized techniques for extraction and purification.

In

49

Indium

58.33

Exploring the Endless Potential of Indium with Recycle Karo

Applications of indium

- Indium is valued for its unique properties in various applications such as in the production of touchscreens, liquid crystal displays (LCDs), solar panels, and semiconductors.

- It is also used as a coating material for bearings and in certain types of solder.

Properties of Indium

- Indium is a soft, malleable, and ductile metal with a low melting point, making it ideal for applications where it needs to form a bond at relatively low temperatures

- It has good electrical conductivity and is highly resistant to corrosion

Recycling Indium with RecycleKaro

Indium can be recycled from end-of-life electronic devices like LCD screens, semiconductors, and solder. Recycling indium helps conserve resources, reduce waste, and meet the demand for this valuable material in various industries. However, the process requires specialized techniques for efficient extraction and purification

Ta

73

Tantallum

58.33

Exploring the Endless Potential of Tantallum with Recycle Karo

Applications of Tantalum

- Highly valued for corrosion resistance and high electrical charge retention, crucial in electronics manufacturing

- Primarily used in capacitors for smartphones, laptops, and medical implants, and in aerospace and chemical processing for heat and corrosion resistance.

Properties of Tantallum

- Dense, ductile metal with outstanding corrosion resistance, especially to acids

- High melting point of 3,020°C, suitable for high-temperature applications

- Exhibits good heat and electrical conductivity

Recycling Tantalum with RecycleKaro

- Tantalum is recycled from electronic devices and industrial waste, reducing environmental impact and conserving resources

- Requires specialized techniques for efficient separation from other materials